Custom Chenille & Varsity Patches in San Diego

We build classic high-pile patches for CIF letterman jackets, vintage streetwear, and team branding. Real felt and yarn construction. not that cheap “fuzzy” embroidery you find at craft stores.

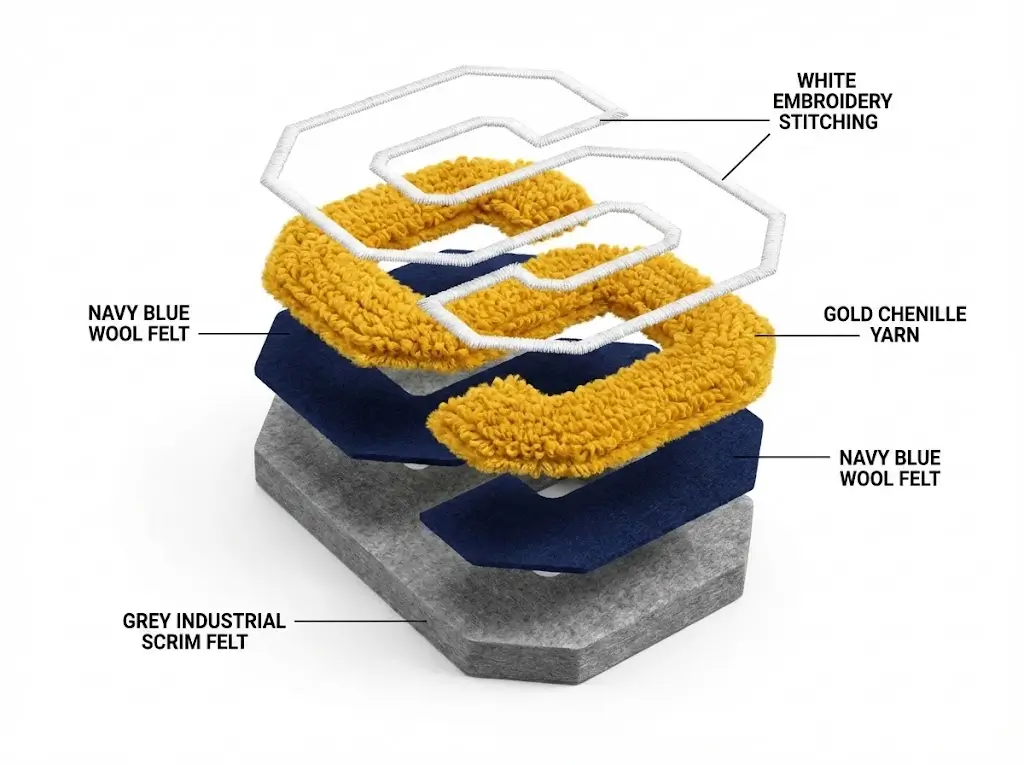

How Real Chenille Patches Are Built

A chenille patch isn’t just stitched; it’s engineered in layers. It needs to be heavy enough to sit on a wool jacket without flopping over.

-

Layer 01

Scrim Felt Base (The Structure)

This is the skeleton. We use a stiff, industrial-grade scrim felt at the bottom. It holds the heavy needle punches and prevents the patch from warping.

-

Layer 02

Top Felt Layer (The Border)

This is the colored felt you actually see around the edge. It acts as the ‘frame’ for the yarn.

-

Layer 03

Chenille Yarn Fill (The Loops)

We drive thick acrylic yarn through the felt to create the ‘moss’ or ‘terry loop’ texture. It stands up. It has depth. It feels like a rug.

-

Layer 04

Embroidery Detail Layer

Chenille is bulky. For sharp outlines or text, we stitch standard embroidery thread on top of the loops. This keeps the edges clean.

Who We Build For in San Diego

From Friday Night Lights to Fashion Valley.

CIF & High School Athletics

- Varsity Letters: Standard 6 inch for chest.

- Mascots: Big 8-10 inch patches for back.

- Activity Bars: 4 inch chevrons/bars for sleeves.

Colleges & Alumni

Fraternities at SDSU and alumni clubs. These are heritage pieces. We match the exact Greek colors so the jacket looks authentic 20 years from now.

Streetwear & Vintage Brands

For the boutique drops in North Park or Fashion Valley. Brands use Chenille to get that 90s retro aesthetic on hoodies and hats.

Car Culture & Motorsports

Car clubs in National City and Chula Vista. Large back patches for club jackets that need to look good cruising down Highland.

Factory Insight: The “Blob Risk”

Chenille cannot do small details.

Think of chenille yarn like drawing with a fat crayon. If you try to write a name or a complex logo under 1 inch tall, the loops will merge into an illegible blob.

The Fix: Mixed Media. We use chenille for the big background shapes and standard embroidery for the fine details.

Big Area = Chenille | Small Detail = EmbroideryStyles We Manufacture

From classic varsity letters to complex mixed-media crests.

Classic Varsity Letters

Double felt backing. 1 to 3 color stacks. The standard for high school awards.

Mascot Patches

We combine the chenille fill with embroidery outlines to make the mascot’s face sharp, not fuzzy.

Year & Award Patches

‘2026’ numbers, Captain stars, and swiss inserts.

Mixed Media Crests

We use a chenille background for texture and stitch the school crest on top. Best of both worlds.

Pricing Logic

Chenille is more expensive than standard embroidery. It uses ten times the thread volume and multiple layers of backing material.

What Changes the Price

Size

A 10-inch back patch uses a lot of yarn. It takes longer to run. That costs more than a 4-inch sleeve number.

Layers of Felt

Single felt is cheaper. Double felt (the standard “varsity” look with two colors) adds material cost.

Mixed Media

If we have to switch the machine head from “Chenille Loop” to “Standard Embroidery” to add a name, that adds runtime.

Quantity & Setup

Setting up a chenille machine is a beast. We have to thread multiple spools of thick yarn. Doing that for 1 patch is expensive. Doing it for 50 spreads the cost out.

Team & Booster Programs

We work with booster clubs across the county. If you order the full season’s batch (letters + numbers + mascots) at once, the price per unit drops hard.

Bundle the roster.

Production Flow

Proofing

We don’t guess. We send a digital mockup showing the felt colors and the yarn texture. You’ll see exactly how the “stack” looks before we cut material.

Manufacturing

San Diego Delivery

We ship daily via UPS/FedEx. If you’re near Kearny Mesa, we can coordinate a pickup for bulk team orders.

Why Work With Us

True Chenille Manufacturing

We don’t fake the look with “zig-zag” embroidery stitches. We use actual yarn loopers. It feels real because it is real.

CIF Size Knowledge

We know the regulations. A Varsity letter needs to be 6 inches. A back patch sits between the shoulders. We won’t sell you a patch that’s too big for the jacket.

Wash-Tested Builds

We use colorfast acrylic yarn. It doesn’t bleed onto the white leather sleeves of a varsity jacket when it gets wet.

Ordering Steps

-

01

Upload Art

Send your school mascot or brand logo.

-

02

Approve Proof

Check the felt colors against your team specs.

-

03

Production

We run the machines.

-

04

Delivery

Shipped to the school or your door.

Get Your Free Quote for Chenille Patches

Stop guessing at prices. Send us your art and specs, and we will give you an exact cost per unit based on thread count and coverage.

Request Quote NowFrequently Asked Questions

Why can’t chenille do small text?

The yarn loops are too thick. It’s like writing with a fat marker. If the text is under 1 inch, the loops merge together and it becomes unreadable. For names, we use standard embroidery on top of the felt.

What size should a varsity letter be for CIF?

The standard for San Diego high schools is 6 inches tall. Sleeve numbers are usually 3 to 4 inches. Back mascots range from 8 to 10 inches.

Is iron-on safe for jackets?

For a wool/leather Letterman jacket? No. The jacket material is too thick for the heat to penetrate and melt the glue properly. Plus, you don’t want permanent glue residue on a $300 jacket. Advice: Sew it on.

Can you mix chenille with embroidery?

Yes. That’s our “Mixed Media” style. We use chenille for the big fill areas and embroidery for the fine details and outlines. It’s the best way to get a clean look.

How do chenille patches handle washing?

Cold wash, air dry. Never put chenille in a hot dryer. The heat can melt the acrylic yarn fibers and ruin the texture.

Best backing for leather sleeves?

Sew-On. Use a heavy needle. It’s the only way to secure a heavy patch to leather.

Minimum order for teams?

We recommend 25 to 50 pieces for the best pricing. We can do small runs, but the setup fee is high.

Can you match school colors?

Yes. We have the standard acrylic yarn colors for all San Diego district schools (Navy, Gold, Cardinal, Forest Green, etc.).

Production time in San Diego?

Chenille takes a bit longer than standard patches. Expect 10–14 days for production.

Do you rebuild old varsity designs?

Yes. If you have a vintage jacket from the 80s and want to replicate the patch, send us a photo. We can digitize it and rebuild it.