Custom Hat Patches Maker In San Diego

Listen, putting a patch on a hat isn’t the same as putting one on a jacket. The geometry is different.

- You need a patch that bends without breaking and sticks without lifting.

- We run these on Barudan machines calibrated for hat stiffener tension.

- We build patches that survive the daily grind for breweries and squadrons.

Get a Hat Patch Quote

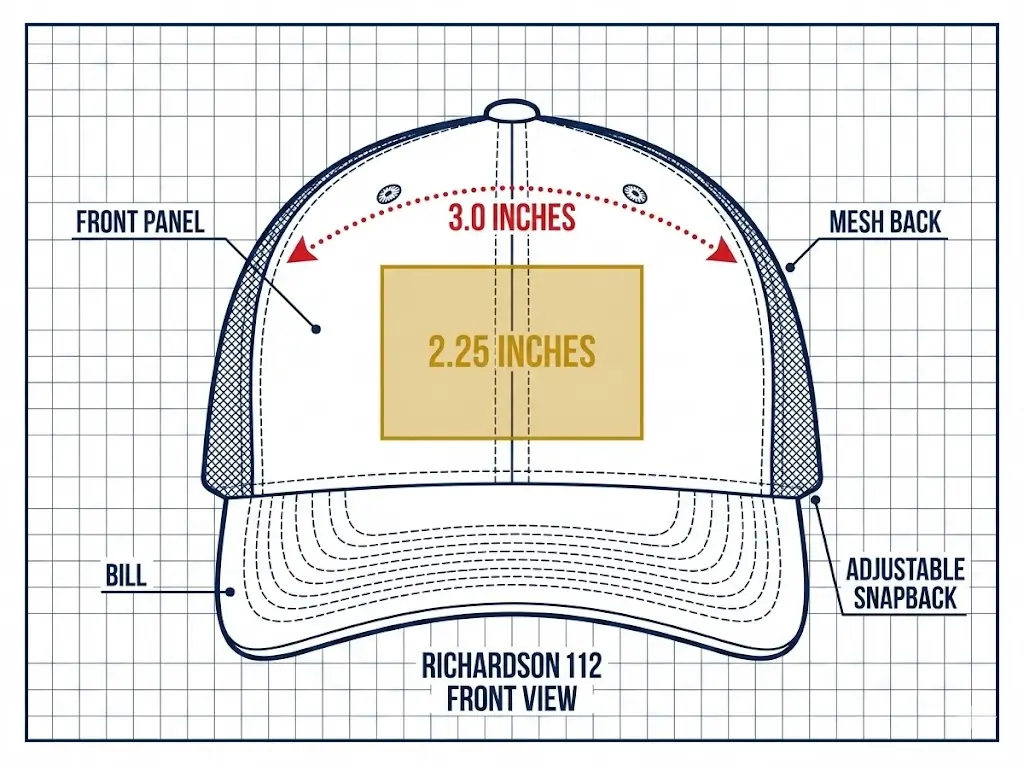

Hat Patch Sizing: The 2.25″ Rule

The #1 mistake rookies make is designing a patch that is too tall.

The Geometry Problem

A baseball cap’s front panel (buckram) curves against your forehead. A patch is naturally flat. If you force a 3-inch tall patch onto that curve, the top corners will lift and gap open. It looks terrible.

The Fix: Max Height 2.25 Inches

This is the sweet spot. It ensures the patch sits flush against the curve of a standard Richardson 112 or Flexfit. Width isn’t an issue (wrap it around!), but height is strictly limited.

Material Options For Hat Patches: Leather, PVC, & Woven

Embroidery is classic, but it’s not always the right tool for the job. Here is how we decide what to run for your order.

Genuine & Faux Leather

This is the standard for the lifestyle brands and breweries over in Sorrento Valley. We laser-etch your logo into the hide. It burns the top layer, creating a dark, recessed contrast. It’s rugged, simple, and ages well.

- The Feel: Thick, rigid, premium.

- The Method: We usually sew these on to guarantee they conform to the hat curve.

PVC (Rubber)

If this hat is going on a fishing boat out of Point Loma or a tactical rig, get PVC. It’s a soft, molded rubber.

- Why: Fabric holds water; PVC sheds it. If you get hit with salt spray, you wipe this patch off. It doesn’t get soggy or mildew.

- The Look: Matte finish, 3D layered depth.

Woven (High Detail)

Embroidery needles have thickness. If your logo has tiny text (like a founding date or a slogan), embroidery thread will turn it into an unreadable blob.

- The Fix: We switch to a Woven patch. It’s made on a loom, not an embroidery machine. The weave is tight and flat, letting us capture razor-sharp details that thread can’t handle.

Attachment Styles: Heat Press vs. Sewing

Listen, you cannot attach a patch to a hat with a standard t-shirt press. It’s flat; the hat is round. You’ll crush the crown.

The Heat Press Method

We use specialized Hat Presses with a curved platen. This matches the radius of the forehead. We apply heat-activated adhesive at 320°F with high pressure. It fuses the patch to the buckram. It’s clean, fast, and looks seamless.

The Sewing Method

This is the tank durability option. We can run a stitch around the perimeter. It’s slower and costs a bit more labor, but that patch is physically locked to the hat. If you are throwing these hats in a washing machine or sweating through them on a job site, sew it on.

Durability: Built for Salt & Sun

San Diego is hard on gear. Between the UV index and the salt air, cheap materials rot.

The Thread

We don’t use cotton. The California sun bleaches it out in a month. We use Solution-Dyed Polyester. The color isn’t just painted on the outside; it’s part of the fiber molecule. Your black patch stays black, even after a summer on a lifeguard tower in Oceanside.

The Glue

The “Marine Layer” (humidity) eats standard sticker backing. It turns it into a gummy mess. We use high-grade industrial heat seals that are engineered to resist moisture.

Turnaround Time & Local Delivery

We don’t overpromise. Standard production takes 10 to 14 days from the moment you approve the digital proof.

Standard Timeline

Our standard production window is 10 to 14 days. This clock starts the moment you approve your digital proof, not the moment you submit the quote.

Local Logistics

If you are local, whether that’s a warehouse in Otay Mesa or an office in UTC, we ship via UPS Ground, which usually hits next-day within the county.

Hard Deadlines

If you have an event at the Convention Center and need these boxes in-hand by Friday, tell us upfront. We can sometimes shift the production schedule to hit your date.

Get Your Free Quote for Yours Hat Patches

Don’t guess on the sizing. Send us your logo, and we will tell you if it fits the 2.25″ rule.

Request Quote NowFrequently Asked Questions

Can I apply these patches with a regular household iron?

Honestly? No. Hats have a structured curve. A flat household iron only hits the center of the patch, leaving the edges loose. Plus, if you push down hard enough to activate the glue, you’ll crush the crown shape. You need a proper Hat Heat Press with a curved bottom platen to apply equal pressure across the forehead. If you don’t have one, let us press them for you, or use a needle and thread.

What is the minimum text size for a hat patch?

For Embroidery, keep letters at least 0.25″ tall. Any smaller and the thread loops close up, making an “A” look like a blob. If you have tiny text like a “Est. 2024” tagline or a phone number switch to a Woven Patch or PVC. They handle micro-details without the bulk of embroidery thread.

Can I wash my hat with a custom patch on it?

It depends on the material.

Embroidered / PVC: Yes. Hand wash in cold water with mild detergent and air dry. Do not put them in a dryer; the heat will melt the adhesive backing.

Leather: No. Do not submerge real leather. It absorbs water, dries out, and warps. Spot clean the hat fabric around the patch only.

Why is the 2.25″ height limit so important?

Geometry. Most trucker hats (like the Richardson 112) have a steep curve on the front panel. If you make a patch 3 inches tall, it fights that curve. The top and bottom will flare out, snagging on everything. 2.25 inches sits flush in the “billboard” area of the cap without lifting.

Do you sell the hats too, or just the patches?

We do both. We can supply the patches loose if you have your own blanks, or we can source standard Richardson, Flexfit, or Yupoong caps and handle the full decoration for you. Sourcing through us usually saves you shipping costs and ensures the patch size matches the hat style perfectly.